1. Why Elevator Inspection Matters

Elevators are among the most regulated mechanical systems found in buildings. Unlike many other amenities, a lift directly carries human life every single day, which is why its operation is governed by strict safety laws and mandatory inspections. Whether installed in an apartment complex, hospital, office building, or mall, an elevator cannot legally operate without approval from the designated inspection authority.

Many people assume that regular servicing by a maintenance company is enough to keep an elevator compliant. While maintenance is essential, it does not replace statutory inspection. Elevator inspections serve a different purpose — they verify that the system meets legal safety standards laid down by Indian regulations and remains fit for public use.

Across India, most elevator-related incidents are linked not to manufacturing defects, but to neglected maintenance records, expired licenses, or bypassed safety checks. This is also why elevators, when properly inspected and maintained, are considered one of the safest modes of transport. This makes inspection a critical safeguard not only for passengers, but also for property owners and associations who carry legal responsibility.

This article explains who is authorised to inspect elevators in India, what inspectors check, how often inspections are required, and who is accountable for compliance. For apartment owners, builders, and facility managers, understanding this process is essential to avoid penalties, shutdowns, and safety risks.

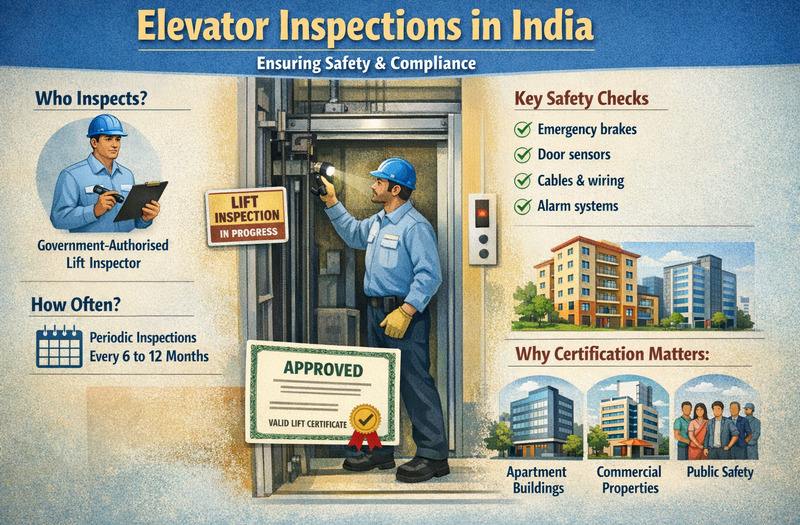

2. Who Is Authorized to Inspect Elevators in India

In India, elevators are inspected by government-appointed authorities, not private companies. The responsibility lies with the State Electrical Inspectorate or Lift Inspectorate, depending on how the state’s lift laws are structured. These inspectors act under the respective State Lift Acts and Rules, which legally empower them to approve, certify, suspend, or shut down elevator operations.

For example, in Karnataka, elevators are regulated under the Karnataka Lifts, Escalators and Passenger Conveyors Act. Similar legislation exists in Maharashtra, Tamil Nadu, Delhi, Gujarat, and other states. While the administrative name may vary slightly, the authority and function remain the same across India.

The lift inspector’s role includes approving new installations before commissioning, issuing operating licenses, conducting periodic safety inspections, and verifying compliance during renewals. Only inspectors authorised by the state government can issue or renew an elevator license. Without this certification, operating a lift is considered illegal, regardless of how new or well-maintained it may be.

It is important to distinguish between government inspection and maintenance checks. Maintenance companies service the elevator to keep it running smoothly, but they cannot legally certify it for operation. Their inspection reports may support compliance, but the final authority always rests with the government inspector.

Lift inspectors also ensure that elevators comply with relevant Bureau of Indian Standards (BIS) codes such as IS 14665 for electric lifts and IS 15259 for hydraulic lifts. These standards define construction quality, safety devices, emergency systems, and inspection requirements. Together with State Lift Acts, they form the legal framework that governs elevator safety in India.

3. What Happens During an Elevator Inspection

An elevator inspection is a structured technical process focused entirely on passenger safety and regulatory compliance. Inspectors do not evaluate design aesthetics or cabin finishes; their concern is whether the lift can operate safely under all conditions.

During an inspection, the lift inspector typically reviews documentation first, followed by physical and functional checks. While the exact procedure may vary slightly by state, most inspections cover the following areas:

- Documentation verification, including installation drawings, load capacity details, maintenance records, and previous inspection certificates

- Mechanical safety checks, covering ropes or belts, braking systems, guide rails, buffers, and car frame integrity

- Door and interlock systems, ensuring doors cannot open unless the lift is level and stationary

- Electrical and control systems, including wiring integrity, control panel function, and fault response

- Emergency systems, such as the Automatic Rescue Device (ARD), alarm button, and communication system

- Load and performance testing, where levelling accuracy, smoothness, and braking response are evaluated

Power failure handling is a critical part of this process, especially in residential apartments and commercial buildings where backup systems are mandatory under safety rules.

Inspectors may simulate fault conditions, such as power failure, to verify that emergency systems respond correctly. If any critical safety item fails, the elevator may be denied certification until corrective action is taken and reinspection is completed.

In many cases, inspection failures occur due to expired ARD batteries, non-functional alarms, poor maintenance records, or unauthorised modifications. These issues are preventable, which is why coordination between the building owner and maintenance provider is essential before inspection.

4. How Often Elevators Must Be Inspected and Who Is Responsible

Elevator inspections are not a one-time requirement. They occur at multiple stages throughout the life of the lift, starting even before the first ride.

A pre-commissioning inspection is mandatory after installation and before public use. Only after the lift inspector approves the system and issues an operating license can the elevator be used. Beyond this, periodic inspections, usually annual, are required to renew the license and confirm continued safety compliance.

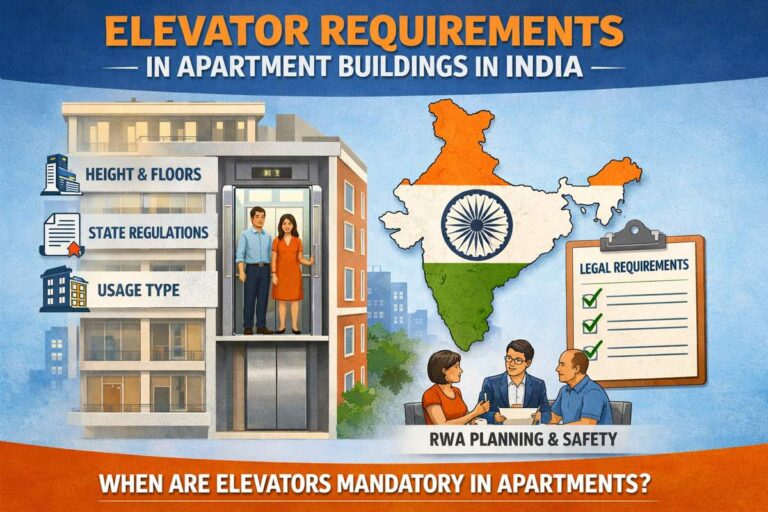

The responsibility for ensuring inspection compliance lies primarily with the building owner or apartment association. In residential complexes, this is typically the RWA or society management. In commercial buildings, it may fall on the property owner or facility management team. Maintenance contractors support the process but are not legally accountable for license validity.

Failure to renew inspection certificates can result in serious consequences. Authorities have the power to issue fines, seal elevators, or order immediate shutdowns if a lift is operating without a valid license. In the event of an accident, expired certification can also expose owners and associations to legal liability.

Inspection expectations also differ slightly by building type. Hospitals and high-traffic commercial buildings are subject to stricter scrutiny due to higher risk exposure. Residential elevators, while less complex, are still required to meet the same core safety standards under the law.

5. Inspection Is Compliance, Safety, and Responsibility

Elevator inspection is not merely a procedural formality. It is a legal requirement, a safety safeguard, and a reflection of responsible building management. A valid inspection certificate confirms that the elevator meets Indian safety standards and is fit to carry passengers without risk.

For apartment associations and property owners, staying compliant protects not only residents and visitors, but also the legal standing of the building itself. Regular inspections, supported by proper maintenance and documentation, significantly reduce the likelihood of breakdowns, entrapments, and regulatory action.

Modern elevators are engineered with multiple layers of safety, but those systems remain effective only when they are inspected, tested, and maintained as required by law. Working with licensed maintenance providers who understand inspection readiness plays a key role in keeping elevators compliant year after year.

In short, elevator inspection is not optional. It is the foundation of safe vertical movement in any building. When inspections are taken seriously, elevators remain one of the safest and most dependable modes of transport in daily life.